About Global Lift Used Forklifts Colorado

Global Lift Colorado - Buying a forklift is not to be taken lightly. A forklift is a big capital expense, and a complex machinery with a motor strong enough to execute heavy-lifting jobs. The price tag for a forklift varies from ten thousand dollars to thirty thousand dollars, comparable to the cost of a small truck. If purchasing a second-hand forklift, be sure to have it inspected for possible mechanical issues.

The two types of forklift motors are: electric or internal combustion. Forklifts with electric motors are typically more pricey than forklifts with internal combustion motors. The motor size should suit the kind of work for which the forklift would be used. A forklift with a large motor costs a lot more compared to one with a motor which is smaller.

Motors which utilize propane or gasoline could lift heavier weights because they are usually stronger than electric motor. The disadvantage is that gas motors tend to develop issues more often than electric motors. Depending on the price of gas or propane, gas powered forklifts can be more costly to run than electric powered forklifts.

Some reputable manufacturers of forklifts are Mitsubishi Caterpillar, Crown Equipment Corp., Toyota Industries and NACCO Industries. Before making a decision, research the various manufacturers and the availability of parts. Prices, reviews and testimonials could be found on the World Wide Web.

Within the US, 20,000 individuals are hurt every year in accidents connected to the utilization of forklifts. And each year about 100 deaths are attributed to forklift accidents. Fortunately, correct training regarding operation procedures and maintenance could considerably reduce the risk of accidents. The basic safety rules and suggestions below must be followed whenever utilizing a forklift.

The employer is responsible for making sure that employees are trained to use a forklift and have undergone a proper training program. Training includes a combination of presentations, lectures, discussions and practical hands-on training. Reevaluation should take place every three years. Forklift operators should be up-to-date with current forklift safety rules. Forklift training program content covers dangers of forklift operations, general workplace hazards, workplace surfaces and lighting, and dangers related to using the specific forklift which the employee would be using. An employee should be at least eighteen years old to use a forklift.

To make sure that the machinery is working properly and safely, forklift inspection should be done each day. The inspection includes keeping a checklist of items and reporting any problems right away.

Having a safe and clean workplace is important in the safe operation of a forklift. A safe work site means establishing "traffic lanes" that are designated for forklift use only. Warning systems like horns and flashing lights should be in place to indicate when there is a forklift approaching. Forklift docking stations should be kept in good repair and inspected on a daily basis.

General safety guidelines for forklift operation consist of respecting the load capacity of the forklift and never exceeding the maximum; avoiding known hazards on the ground, like wet spots or oil spills; lowering or raising the load only when the forklift is stationary; ensuring there is enough clearance for the load; and keeping arms, legs and hands in the vehicle during operation.

Nearly all businesses need a reach truck that helps them get the task done fast and efficiently. At the end of the day, these are among the important factors that will enable the business to earn the most money. The Crown family of reach trucks offers you with more for your investment in different ways. Like for example, these machinery deliver smart traction together with responsive controls. The state-of-the-art ergonomics provide the operator with a major edge.

These narrow aisle reach trucks can achieve great capacities, visibility, heights and energy savings. Crown's machinery provide numerous strong and reliable machines which could endure harsh settings. They provide accurate load handling and increasing pallet moves with phenomenal lift and travel speeds. The reliability is well documented and leads to driving overall expenses down while offering industry-leading uptime and maintenance simplicity.

The Crown reach truck family is made up of the RR 5700 Series, the SR 5000 Series and the RM 6000 Series. Particularly, the Crown RR 5700 delivers the best performance in the reach truck business for travel and lower/lift functions.

The RD 5700 is a helpful workhorse of a machinery which also offers great durability. This particular model provides optimal use of space without losing any operator comfort. The most advanced design and performance as well as innovative technology all come together in this series. Crown also offers their exclusive Access 123 Comprehensive System Control to provide great service team accessibility and operator control.

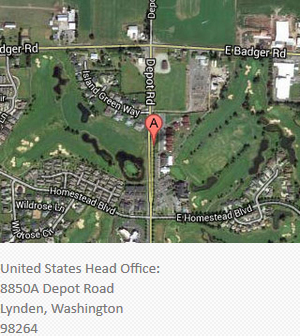

Contact Info

Fax: 1-888-029-0202

Fax: 1-888-029-0202

Questions or Comments